& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Validate design and make skills to get hired, advance your career, and accelerate your business.

Deeply researched with industry partners, Autodesk certifications measure the skills required for design and make workflows.

Whether starting out or looking to expand to new roles, Autodesk certifications provide recognition of expertise to accelerate careers.

Future-focused certifications help organizations differentiate talent and innovate with new technologies, skills, and productivity.

AEC professionals and students can earn Autodesk certifications to highlight their knowledge and skills in CAD and BIM tools.

Product design and manufacturing professionals and students can earn Autodesk certifications to showcase their skills in CAD, CAM, design-to-manufacture workflows, and more.

Media and entertainment professionals and students can earn certifications demonstrating their knowledge and take their careers to the next level.

Developed for secondary students and non-English speakers in all industries, this certification validates and highlights foundational Autodesk software skills and knowledge.

Designed for students in higher education and others with essential knowledge and skills in Autodesk software who are ready to enter the job market or pursue a new career path.

For candidates with advanced skills and can solve complex challenges, this certification helps candidates stand out and succeed in a competitive job market.

For candidates to showcase their in-depth knowledge, the expert-level certification signals leadership and commitment to mastering skills in leading-edge workflows.

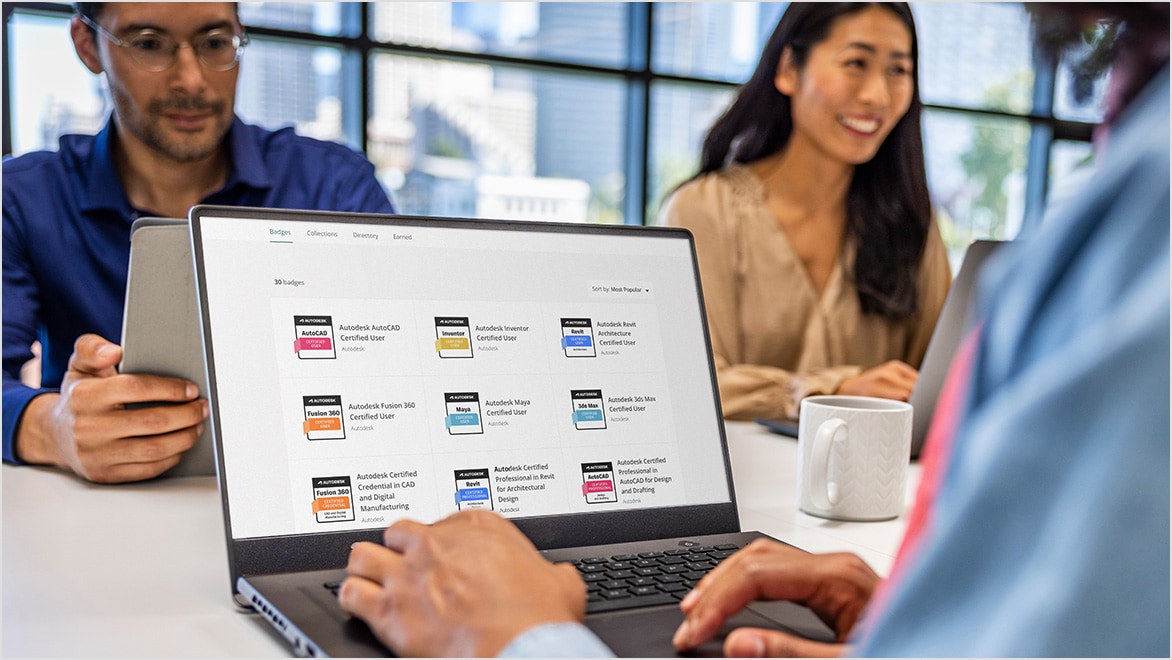

Autodesk partners with Credly to offer digital credentials to showcase your achievement or discover and verify talent for your organization.

Build, validate, and showcase in-demand skills to succeed in today’s evolving industries. Whether you’re starting your career or expanding your skillset, take immediate steps toward your goals with Autodesk certification resources.

Set yourself up for success by taking a prep course with practice tests. Courses cover the core skills and knowledge you need to succeed in the exam.

Find the learning content that’s right for you, track your progress, and discover the next steps on your learning journey.

Autodesk Learning Partners (ALPs) are available to help provide vouchers for certification exams in bulk and prepare groups for certification success.

For more FAQs, visit our Support & Policies page.

Certifications are valid for 2 or 3 years, depending on which certification you earn. For example, Fusion 360 certifications are valid for 2 years, while other certifications are valid for three years. See the certification details for each of the certifying validity periods and other information.

Autodesk is pleased to offer ACA, ACP and ACE certifications. Standard Retail Prices for each of our exam tiers are as follows:

Certification type |

Standard Retail Price* |

Autodesk Certified Associate (ACA) |

$150.00 (USD) |

Autodesk Certified Professional (ACP) |

$200.00 (USD) |

Autodesk Certified Expert (ACE) |

$250.00 (USD) |

*All exams are priced according to currency values in specific countries and regions. Exam prices are subject to change. In some countries and regions, additional taxes may apply.

Choose which Autodesk Certification you would like to earn from the available certifications by industry above.

For Autodesk Certified User exams:

Selecting an ACU exam will transfer you to our testing partner Certiport. You can complete the sign up and scheduling process from Certiport's site.

For Autodesk Certified Associate, Professional, and Expert exams:

Select a certification to find out details and select the "Get certified" button to start your exam application. If you haven't already, you will be asked to sign in to your Autodesk Account. Fill out the exam application and submit it. From there you will be able to select from your Certification Dashboard an action to sign up for an exam appointment either in-person at a Pearson Vue testing center or for an online exam. Note you will need to provide proof of identity at exam time.

Ready for your exam?

For more information, please see our Support and Policies page.